Home | Hot-dip galvanizing

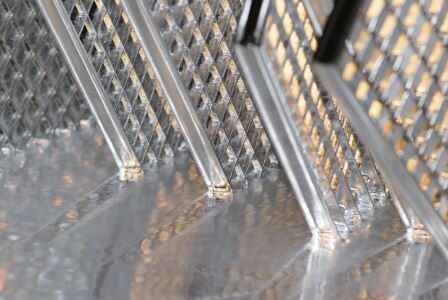

90 percent of our products are hot dip galvanised. In hot-dip or batch galvanizing, finished steel components are immersed in a hot, liquid zinc alloy at 450 degrees Celsius. The zinc coating, which protects the components against corrosion, is created by the mutual diffusion of zinc and iron. Compared to other corrosion protection systems such as coatings or paints, hot-dip galvanizing is characterized by a particularly long service life: The zinc coating protects the steel for up to 100 years without the need for maintenance or servicing measures.

Hot-dip galvanised steel structures are also optimally protected against mechanical influences – even with regular assembly and disassembly, hot-dip galvanized components, such as gratings, can be used for decades. In the event of defects or weakening corrosion protection, hot-dip galvanized steel components can be re-galvanised and reused without any loss of quality. At the end of its useful life, hot dip galvanised steel can be recycled as often as required, i.e. melted down and moulded into new steel products. The industry-wide recycling rate for hot dip galvanised steel is currently 88%, while the recycling rate is 11%. In the recycling process, the evaporating zinc is also collected and reused.

These properties make hot dip galvanised steel an important component of the circular economy as a circular material and building material.

There is no question that hot-dip galvanizing is an energy-intensive process in which pollutants are emitted and environmentally sensitive substances are used. Among other things, our zinc baths have to be kept at a temperature of 450 degrees Celsius 365 days a year. Chemicals such as hydrochloric acid are needed to prepare the steel for galvanizing. Keeping the environmental impact of our activities as low as possible and ensuring the highest level of occupational safety for our employees has always been a principle of the Lichtgitter Group.

EUROPE’S MOST MODERN VERZINKEREI GROUP

With our four plants in Heek, Stadtlohn, Sulz and Glos (France), we are the most modern Verzinkerei group in Europe. State-of-the-art facilities, computer-aided processes and, last but not least, our experienced and well-trained employees ensure that we are the benchmark for the industry in terms of quality, service and sustainability.

Commissioning: end of 2013

Size: over 12,000 m2 of covered hall space for finishing, order picking and storage

Boiler dimensions: L 8.00 x W 1.45 x D 3.2 m

Commissioning: early 2001

Size: 6,500 m2 of covered hall space for finishing, order picking and storage

Boiler dimensions: L 7.00 x W 1.20 x D 2.50 m

Commissioning: early 2009

Size: 4,500 m2 of covered hall space for finishing, order picking and storage

Boiler dimensions: L 7.20 x W 1.30 x D 2.80 m

Commissioning: mid-2024

Size: 5,000 m2 of covered hall space for finishing, order picking and storage

Boiler usable dimensions: L 7.00 x W 1.45 x D 3.00 m

Our journey to greater responsibility continues – you can find more insights here.