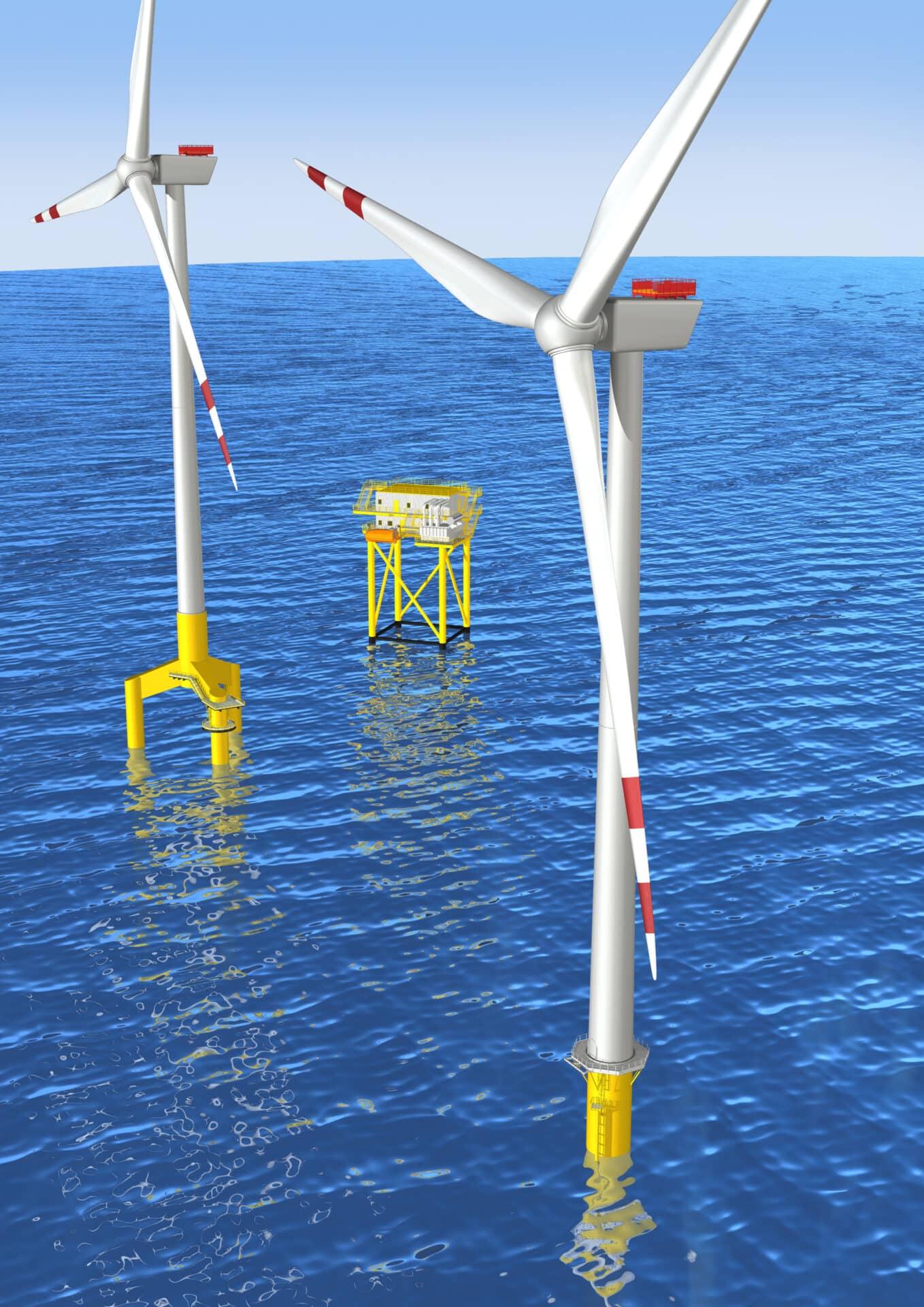

Individually tailored offshore solutions for the wind power sector

Home | Industries | Offshore

Particularly in the offshore sector, special demands are placed on the product and the supplier. This brings with it extraordinary qualitative and logistical challenges. To minimize interfaces, we offer an extensive, high-quality range of industrial floor coverings. Discover where our products are used.

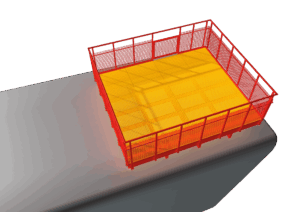

People are lowered onto the helicopter platforms made of GRP-profiles and gratings by helicopter. In addition to the usual properties of GRP-Products, the platforms are characterized by low maintenance and high strength.

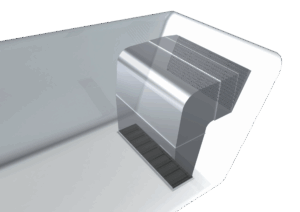

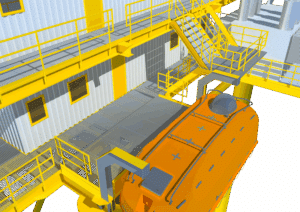

To cool the oil inside the engine room, air from the environment is fed to the oil cooler via an intake filter. With the help of a special "sandwich" base made of Duplex-coated press-locked gratings, pedestrian traffic units, filter fleece and counter bearing can be realized in one

component. The filter can be easily replaced by simply dismantling the counter bearing without the need for additional safety measures. This reduces maintenance costs.

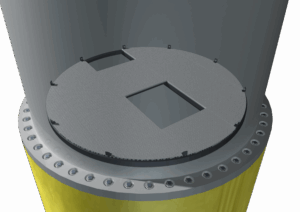

The internal platforms in the wind turbine tower can be equipped with different floorings. Industrial floor coverings are ideal for this purpose. In addition to the familiar grating variants as forge-welded gratings and press-locked gratings made of steel, stainless steel or aluminum, perforated metal planks with different surface textures, GRP gratings or chequer plate gratings can also be installed.

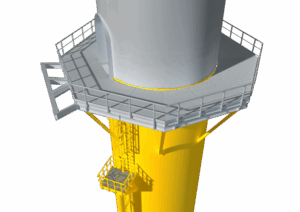

In the lower area of wind turbines, the maintenance platform provides a stable storage area for containers and material. Corrosion-resistant and lightweight components from the Lichtgitter Group are used for the floorings and equipment - ideal for permanent outdoor use in changing weather conditions.

Stair treads are offered in the same variants as industrial floor coverings - whether made of steel, stainless steel, aluminum or GRP. Different versions with serrated nosing, sideplates or reinforcements are available to suit the area of application and safety requirements.

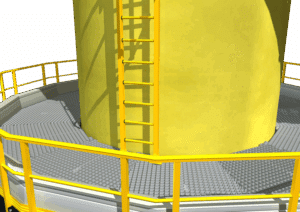

The GRP-vertical ladders from the Lichtgitter Group offer a reliable solution for vertical access in industrial applications. Manufactured from glass fiber reinforced plastic profiles in accordance with EN 13706 (type E23), they impress with their high weather resistance.

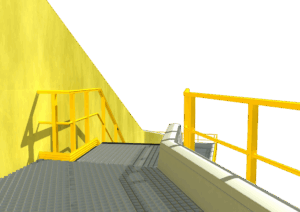

The GRP railing system from the Lichtgitter Group is made from glass fiber reinforced plastic profiles and is suitable for a wide range of applications. It is corrosion-resistant, extremely lightweight and can withstand high mechanical loads.

The Lichtgitter GRP cable ducts are manufactured on the basis of a high-quality resin reinforced with glass fibers and can be used in all weather conditions.

The closed system protects the installed cables permanently - while at the same time being lightweight and easy to work with.

The BN-OF fire-retarding coverings replace conventional coverings with coarse ballast ballast coverings with a functional, maintenance-friendly solution. It inhibits the development of flames in the event of fire, is serrated in accordance with rating group R 11 as per BGR 181 and is suitable for offshore applications thanks to its robust design.

Benefit from the general building approval!

Lichtgitter GRP gratings meet the requirements so that you can carry out your construction projects

properly. This gives you the assurance that you can use our GRP-

Gratings without ZiE / approval in individual cases.

Benefit from the general building approval!

Lichtgitter GRP gratings meet the requirements so that you can carry out your construction projects

properly. This gives you the assurance that you can use our GRP-

Gratings without ZiE / approval in individual cases.

Made of glass fiber reinforced plastic (GRP), the helicopter platforms are designed for the safe transfer of people by helicopter. The construction is based on GRP-profiles and Gratings, which are characterized by high strength, low weight and resistance to corrosion and weathering.

Another advantage is the low maintenance requirements of the platforms, which is particularly important for long-term outdoor use. To ensure safe operation, solutions for the controlled dissipation of static charges that can occur when helicopters approach and land are integrated.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

For efficient cooling of the oil in the engine room, ambient air is fed to the oil cooler via an intake filter. The construction is based on a so-called “sandwich” base made of duplex-coated press-locked gratings, which combines several functions in one component: It is pedestrian trafficable, contains the filter fleece and the associated counter bearing.

A major advantage of this system is the ease of maintenance. The counter bearing can be dismantled without additional effort, allowing the filter insert to be replaced quickly and without further safety measures.

The compact design helps to reduce maintenance times and costs and offers a reliable solution for continuous operation in industrial applications.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

The internal platforms of wind turbines can be equipped with different industrial floorings – tailored to the function, load and environmental conditions.

Forge-welded gratings and press-locked gratings made of steel, stainless steel or aluminum are used. In addition, perforated metal planks with different surface structures, chequer plates and gratings made of glass fiber reinforced plastic (GRP) are available as alternatives.

The selection of suitable floorings depends on the requirements, such as slip resistance, corrosion resistance or weight.

The maintenance platform is positioned in the lower area of the wind turbine and serves as a parking and storage area for containers, tools and materials required for maintenance work.

Various coverings from the Lichtgitter Group are available for the platform design. Gratings made of glass fiber reinforced plastic (GRP) are frequently used. GRP-railings and GRP cable duct systems can also be installed. These components are characterized by their low weight, high weather resistance and long service life – ideal for outdoor use with minimal maintenance.

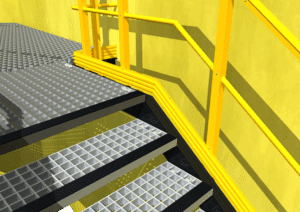

Stair treads are manufactured in the same types and surfaces as press-welded gratings, press-locked gratings,

perforated metal planks and GRP gratings.

Steel grating steps are always supplied with a serrated perforated nosing and welded sideplates. The perforated nosing increases the structural value and visually marks the front edge of the step in a particularly advantageous way, which contributes significantly to safety.

GRP grating steps can be designed with a black sanded flat material in the tread area or with a tread angle for static reinforcement. The GRP-stairtreads are supplied without sideplates as standard, but can optionally be bolted with a sideplate made from a GRP angle.

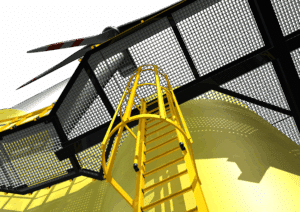

The Lichtgitter GRP-vertical ladders are characterized not only by their weather resistance and long length, but also by their low weight. They are manufactured

from GRP-profiles in accordance with EN 13706, type E23. The profile is designed as a serrated rung profile. The GRP-vertical ladders are reinforced with PE materials in the screw connection area.

The Lichtgitter GRP railing system is made of glass fiber reinforced plastic profiles. It can support high loads, is weather-resistant and very light. It can be used both as a horizontal and as a stair railing system.

Lichtgitter GRP cable ducts are manufactured on the basis of a high-quality resin reinforced with glass fibers and can be used in all weather conditions. They are UV resistant and have good fire behavior properties. Thanks to their closed system, they offer good protection for the cables against aggressive media and weather influences. Further advantages of the cable trunking system are its low weight and the ease with which the profiles can be handled and processed.

The BN-OF fire-retarding coverings have established themselves as an alternative to conventional transformer coverings with coarse ballast. Due to the limited air permeability, the flames are contained and delayed in the event of a fire. The fire-retarding coverings, which are based on the BN-O sheet metal profile grating type, are also the optimum solution for transformers in the offshore sector. Optimized for this application, the coverings have a very good surface structure and are serrated up to rating group R 11 in accordance with BGR 181 thanks to the open nobs pressed upwards. The downwardly shaped openings allow a maximum flow of oil, extinguishing water and rainwater. Thanks to their low dead weight, the coverings can be installed and removed quickly, reducing maintenance and shutdown costs for the prescribed inspections and leak tests.