Do you have any questions?

- William Gietmann

- General Sales Manager

- Wilhelm.Gietmann@lichtgitter.com

- +49 2563 911-134

Gratings are self-supporting, differently load-bearing (e.g. suitable for vehicle traffic or pedestrian traffic) plate-shaped bodies with many continuous openings, the so-called meshes.

Lichtgitter was founded in 1929 as a company specializing in the manufacture of gratings and is now one of the world leaders in the production of gratings. In the future, we will continue to devote particular attention to the pioneering development of production and application technology solutions, especially in the Gratings sector.

Today, in addition to the familiar variants of press-locked gratings and press-locked gratings made of steel, stainless steel and aluminum, we can also supply you with gratings made of GRP material as GRP gratings and as a combination product – gratings with on top welded grating chequer plate.

Gratings consist of vertical bearing bars arranged parallel to each other. The bearing bars are crossed and connected by cross bars at regular intervals. Gratings are provided with an all-round binding bar / banding made of flat material or a T-profile. The best-known types of grating are forge-welded gratings and press-locked gratings. Gratings are mainly made of steel, but can also be made of aluminium, stainless steel or glass fiber reinforced plastic. The preferred surface treatment is hot-dip galvanizing, which is carried out in accordance with DIN EN ISO. Stainless steel and aluminum gratings, on the other hand, are mainly pickled.

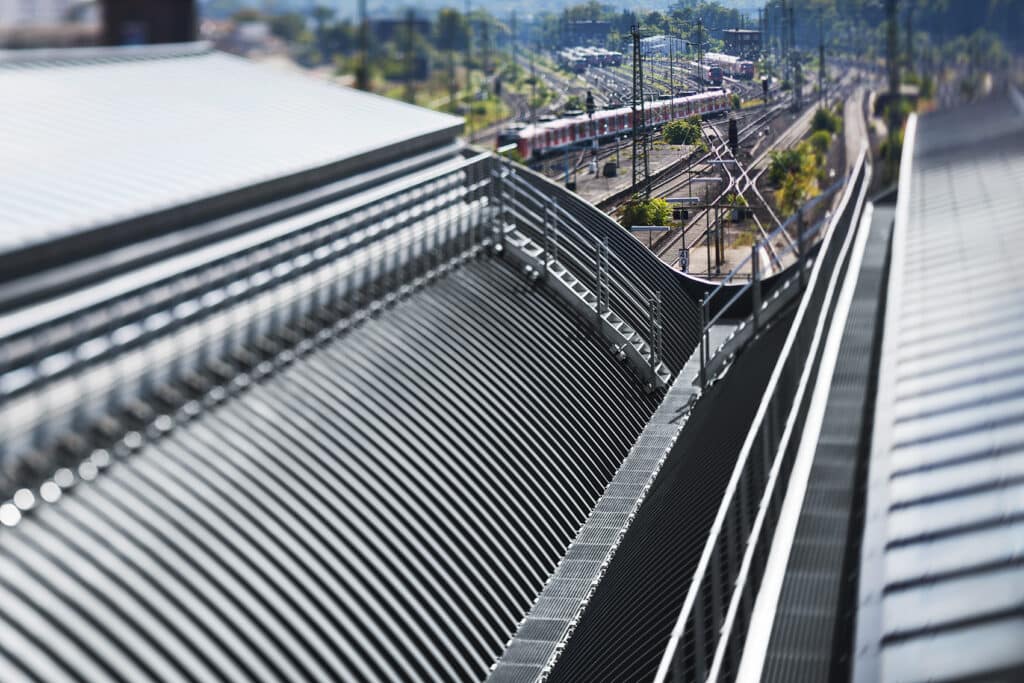

Gratings are used as easy-to-install load-bearing prefabricated elements, particularly for pedestrian traffic and vehicle traffic, coverings, platforms, walkways, stairs, platforms, steps and much more. This type of metal grating is innovative due to its versatility. Gratings are also impressive in the architectural sector. For example, grating steps are often used for spiral staircases. This is because the advantages of using Gratings are unbeatable. Good light and air permeability, high bearing capacity with low dead weight, easy installation and removal, a slip-resistant surface and the fact that liquids and dirt cannot accumulate are just some of the arguments in favor of gratings.

Our range includes steel, stainless steel, aluminum and GRP gratings as well as combi decks with chequer plates.

Perforated metal planks are profiled and C-profiled components that perfectly complement our product range.

In addition to Gratings, we also offer constructions and profiles made of glass fiber reinforced plastic (GRP).

Our straight staircases and spiral staircases stand for precision, durability and tested safety - 100% "Made in Germany"

We slit our own steel and also offer these semi-finished products, such as hot wide strip, to other companies.

Hot-dip galvanizing is the optimal corrosion protection for steel. We are the most modern galvanizing group in Europe - with currently 4 locations.

Our powder coating not only gives metal surfaces an attractive appearance, but also provides excellent protection against corrosion.

Our range also includes wire mesh flooring, welded wire mesh and wire mesh mats, which we sell through Draht Müller, a company belonging to the group

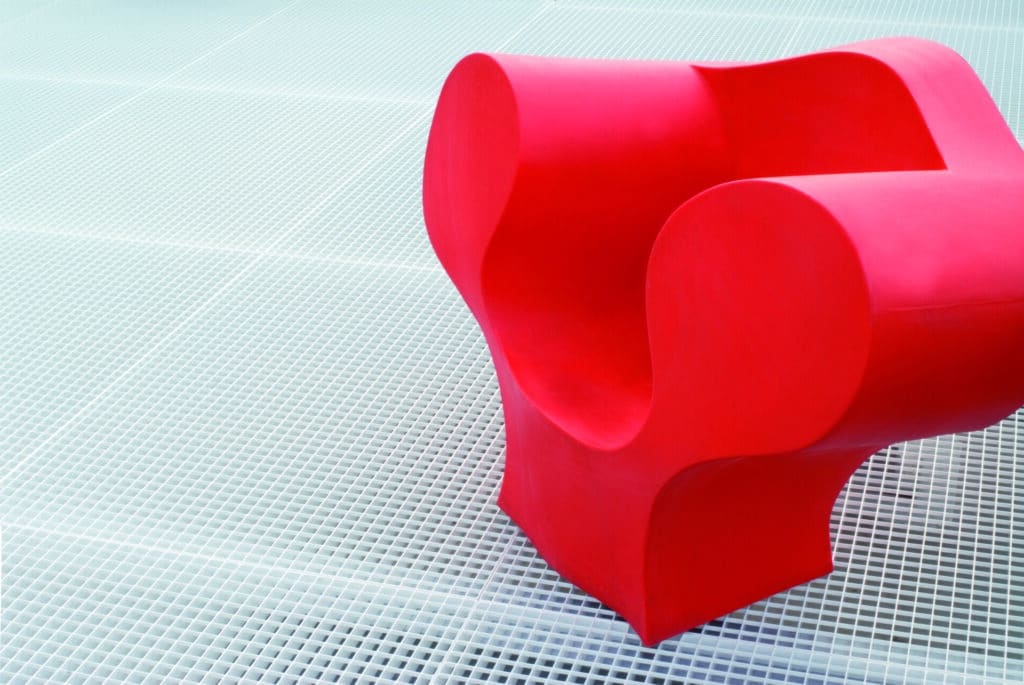

Gratings can be made of glass fiber reinforced plastic (GRP) in addition to the familiar materials of steel, stainless steel and aluminium. Gratings are molded in special molds, known as molds. The glass fibers are woven into the composite and the resin, additives and possibly color pigments are added in liquid form. In addition to these different materials, there are endless other design options. Gratings differ in the height of the bearing bars, the mesh and the surface treatment. Our combi decks, a combination of Gratings and chequer plates, also show how versatile the product is. The advantage of combining grating with chequer plate is that the chequer plate improves walking on the grating and makes it non-slip by increasing the height of the cheeks.

The Lichtgitter Group has an extensive stock program. You can obtain storage gratings and storage steps in the various grating types and standard dimensions from stock within 48 hours. However, we do not only offer standard designs. The majority of our products are made to measure. A wide range of types, individual dimensions, cut-outs or customizations are no problem for us. The Gratings we offer are:

You will find the right fixing material for the products mentioned in the Accessory section. Of course, our range also includes a large number of special gratings, such as louvres gratings, barefoot gratings and comb gratings. So if your challenge is not yet covered by our product range, this does not mean that we cannot also provide you with what you need. Talk to us about your requirements and we will work out a detailed Gratings solution specially developed for you on this basis.

Lichtgitter was founded in 1929 by Carl Martin and the Englishmen Allan and Allan Norman Kennedy. Since the company was founded, our passion has been the manufacture of Gratings and industrial floorings of all kinds. This is reflected in the fact that our company is now in its 3rd generation and is still family-run. Not only are the quality of our Gratings, and therefore customer satisfaction, important to us, but the sustainability of our products is just as important to us as the satisfaction of our employees. Our head office is located in Stadtlohn, in the western Münsterland region directly on the Dutch border. The Lichtgitter Group has several subsidiaries and associated companies around the world and is now one of the world’s leading grating manufacturers.