Home | Produkte | GRP-Products | GRP Gratings

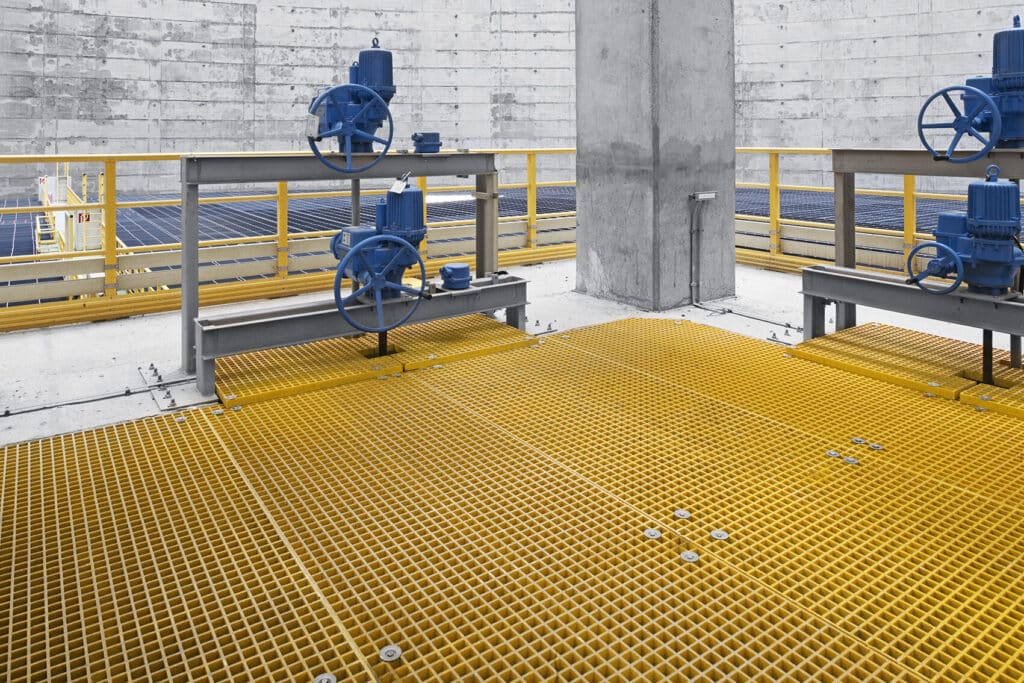

Molded GRP gratings are produced in a negative form in a so-called “mold”. The appropriate mold is selected depending on the design of the grating, grating height, pitch and width of bars. Glass fibers are then woven into the composite. The resin mix is produced in a mixing plant. This consists of the resin, e.g. Isophtal resin, color pigments and additives for fire behavior and UV inhibitors. The mix is then also poured into the mold, the glass fibers are pressed down again with a comb and the mold is then heated. The material hardens when heated harder. When the Gratings has cooled down, it is pressed out of the mold.

Lichtgitter has a wide range of grating designs and different panel sizes. In addition to the stock panels, many other designs, dimensions and colors can also be produced. We can manufacture the individually required dimensions from the standard panels available from stock. The panels are cut to size using state-of-the-art CNC systems and panel saws.

We were the first company to receive building authority approval (abZ) from the German Institute for Building Technology (DIBT) for our GRP gratings. This involved a lengthy certification process and various destructive and non-destructive product tests. The manufacturing plant and the monitoring of the tests are regularly checked by accredited bodies.