Press-locked gratings are one of the most frequently used types of grating today. They are used in the civil engineering sector as well as increasingly in the architectural sector.

In press-locked grating production, unweakened cross bars are pressed into specially slotted bearing bars using high pressing pressure. Lichtgitter manufactures over 15,000 different types of press-locked grating in steel, stainless steel and aluminum on its flexible production facilities.

Gratings can be used for a wide variety of purposes. Different types of Gratings can be used for this purpose. The most commonly used variant is press-locked gratings. Find out below what the differences are to other types of Gratings and what the advantages and disadvantages of press-locked gratings are.

What makes a press-locked gratings?

The fact that press-locked gratings are the most commonly used type of grating in many European countries today is primarily due to the wide range of design options. Due to its manufacture, in which prefabricated cross bars are pressed into specially slotted bearing bars, and the variety of materials that can be used, a wide range of grating designs can be produced individually according to customer requirements and the intended use.

The many possible combinations of materials, surface treatments and grating designs allow a wide range of possible shapes and designs of Gratings to be produced. During production, the cross bars, which are usually made of cold-rolled steel, are pressed into the pre-slotted bearing bars under high pressure. The edge of the Gratings is edged with a beaded strip, flat material or T-profile.

To minimize the risk of slipping on the grating, these can be provided with a special serrated surface. For this purpose, the tops of the supports and/or cross bars are notched accordingly.

Difference between press-locked gratings and forge-welded gratings

In contrast to press-locked gratings, twisted or round cross bars are used in forge-welded gratings. In addition, the individual supports and filler bars are not welded together in press-locked gratings, but are simply pressed into place under high pressure to achieve their strength. Only the binding bar / banding is welded on and thus holds the inner bars in position like a frame.

The production process of a forge-welded grating differs from that of a press-locked grating in that twisted or round cross bars are pressed into the unweakened bearing bars under high pressure, but are also fully welded at the same time. This ensures a high level of step safety and a very high bearing capacity of the Gratings.

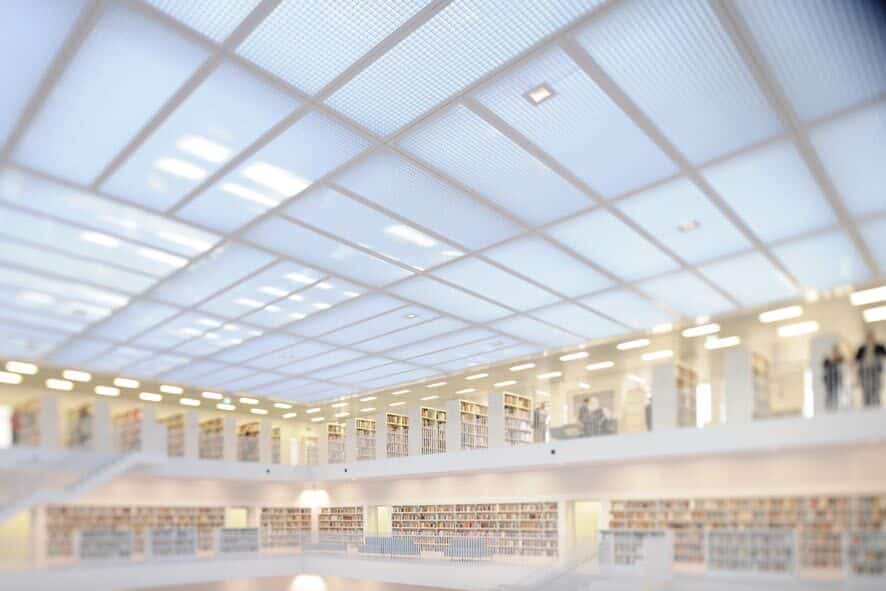

Press-locked gratings can be used in a variety of ways. They are used in industrial and commercial applications as well as in the private and architectural sectors. Thanks to the special production process, different heights of the individual bars and different sizes of grating mesh are possible.

Possible areas of application for press-locked gratings are:

– Light wells to cellar rooms

– Stages and platforms

– Walkways and bridge constructions

– Stair treads and balconies

– Facades and ceiling coverings

– Railing fillings

– Shelves

Despite their low weight, press-locked gratings have a high bearing capacity and excellent torsional rigidity. However, for extremely high loads, especially in the industrial sector, specially manufactured heavy duty gratings should be used.

As an alternative to the frequently used press-locked gratings, special gratings such as full cell gratings or barefoot gratings can also be used or other designs as required

All of these gratings have their own advantages and disadvantages. The perfect Gratings can be selected depending on your design wishes and requirements for the material and bearing capacity. With the appropriate Accessory, each of these gratings can be easily installed.